Features

Single-switch Selection of intermittent or Continuous operation.

Equipped with Ace Controller GK Series.

Efficient, Economical and Dependable… One compressor, double the function. A single switch allows selection of either continuous or intermittent compressor operation, so there’s no need to choose a compressor for just one particular application. When used in the intermittent operation mode, starting and stopping are smoother because the compressor stops and restarts after idle running in an unloaded state. The unloaded state of GK Series compressors during intermittent operation reduces oil consumption and significantly improves the durability of most parts, resulthing in lower operating costs. Stopping in an unloaded state means there’s no sudden sound of air discharge typical of conventional intermittent-operation compressors.

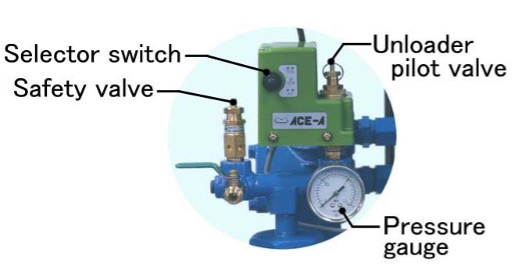

What’s an ACE Controller?

Advanced Controller for Economical Operation

An ACE controller combines the functions of an unloader pilot valve and a pressure switch to allow one-touch switching between continuous and intermittent operation. It also functions as a Safety start/stop switch. When the pressure setting was reached in previous models during intermittent operation, activation of a pressure switch immediately stopped the compressor, exerting a strain on the moving parts and causing partial overheating, leading to excessive wear. In the GK Series with the ACE controller the compressor idles (in a no-load state) for 40 to 50 cycles before stopping, giving the cylinders and other parts a chance to cool down and allowing the moving parts to come to a smooth stop. Starting is also smoother, further reducing piston ring and bearing wear. The result is longer component life and enhanced durability.

What’s the difference between a Single-stage and 2-stage Compressor? (GK-37A ~ 150D)

Single-stage compressor draws in air and compresses it all at once to the pressure setting. 2-stage compressor first compresses the air to an intermediate pressure and cools it in a low-pressure cylinder, then compresses it to the pressure setting in a high-pressure cylinder. When air is compressed it becomes very hot, wasting energy and causing deterioration and carbonization of the compressor oil. Air does not get as hot in a 2-stage compressor, so the temperature of the discharged air is lower and less oil is consumed. Operating noise is also reduced.

Technical Specifications

| Model No. | GH-15BK | GH-22CK | GK-37A | GK-55E | GK-75D | GK-110D | GK-150D | |

| Motor output | kW(ps) | 1.5(2) | 2.2(3) | 3.7(5) | 5.5(7.5) | 7.5(10) | 11(15) | 15(20) |

| Operating pressure | MPa[kgf/cm2] | 0.78~0.98[8~10] | ||||||

| Free air delivery | L/min | 160 | 240 | 430 | 700 | 840 | 1360 | 1660 |

| (cfm) | 5.7 | 8.5 | 15.2 | 24.7 | 29.7 | 48 | 58.6 | |

| Basic compressor | Rotating Speed(rpm) | 975 | 985 | 950 | 1024 | 870 | 945 | 1050 |

| Model No. | GNO-2C | GNO-3C | BT-37 | BT-55H | BT-75C | BT-110C | BT-150CP | |

| Air tank capacity | L | 73 | 80 | 119 | 159 | 244 | 260 | 260 |

| (gal) | 19.3 | 21.1 | 31.7 | 42 | 63.4 | 68.7 | 68.7 | |

| Air outlet dia.×qty. | B | G1/4×1 | G1/4×2 | G1/4×1 | G1/4×1 | G1/4×1 | G1/4×1 | G1/4×1 |

| Rc1/2×1 | Rc1/2×1 | Rc3/4×1 | Rc1×1 | Rc1×1 | ||||

| Approx. dimensions | L:mm | 1130 | 1227 | 1377 | 1395 | 1560 | 1660 | 1660 |

| (in) | 44.488 | 48.307 | 54.252 | 54.921 | 61.417 | 65.354 | 65.354 | |

| W:mm | 394 | 394 | 425 | 500 | 600 | 620 | 620 | |

| (in) | 15.512 | 15.512 | 16.732 | 19.685 | 23.622 | 24.409 | 24.409 | |

| H:mm | 758 | 770 | 890 | 1065 | 1150 | 1234 | 1242 | |

| (in) | 29.843 | 30.315 | 35.039 | 41.929 | 45.276 | 48.583 | 48.897 | |

| Noise level | dB(A) | 73 | 74 | 74 | 75 | 76 | 78 | 80 |

| Weight | kg | 98 | 115 | 183 | 281 | 319 | 427 | 466 |

| (including motor) | (bls) | 216 | 254 | 403 | 620 | 701 | 939 | 1027 |